composite glazing

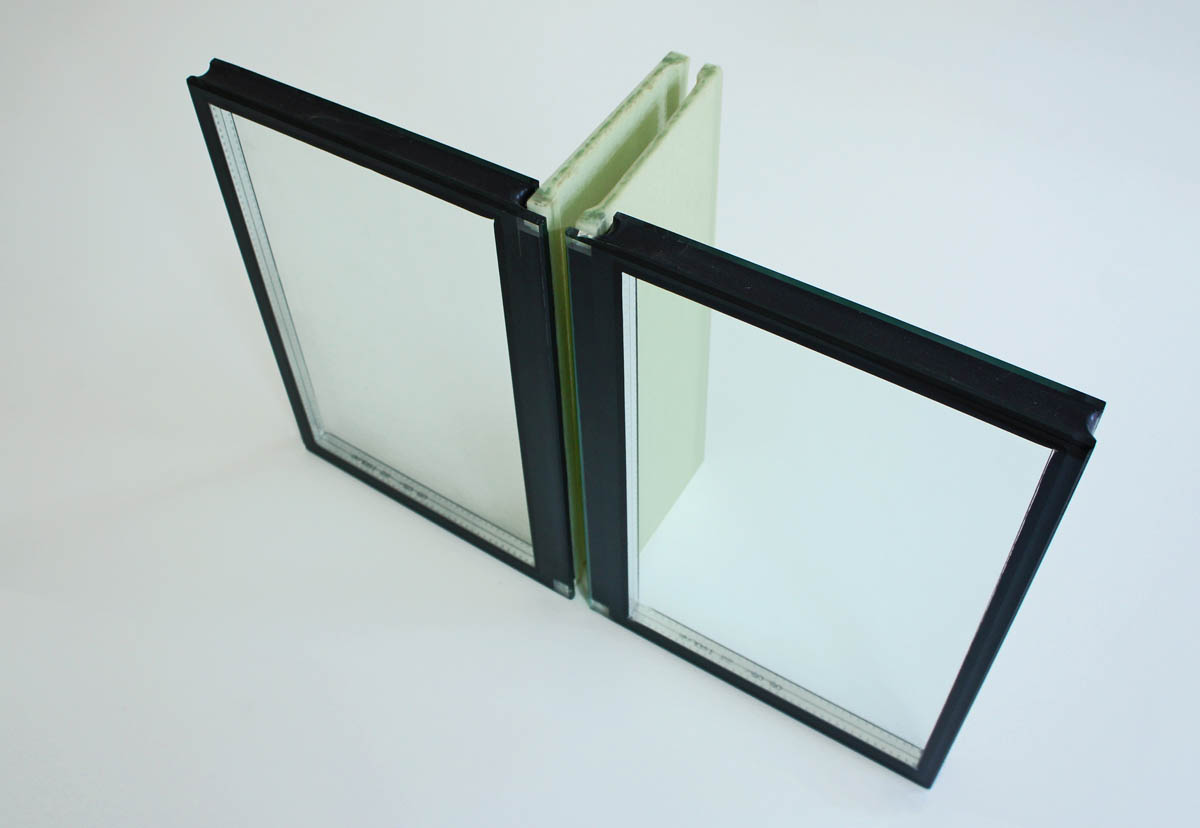

Product developmentComposite Glazing was developed with the Danish company Fiberline Composites and reached product maturity with the Swiss company Glas Trösch for the manufacture of large-format glazing with minimized profile thicknesses. The principle is based on the load-bearing composite of the glass panes with pultruded GRP profiles, which are bonded directly to the panes and take over the function of the otherwise standard facade profiles. This is made possible on the one hand by the comparatively low heat transfer coefficient of GRP, which allows the profiles to be arranged directly behind the glass panes without a thermal separation plane. On the other hand, GRP and glass have the same coefficient of thermal expansion, which makes a bonded connection possible without leading to temperature-related constraints. At the same time, the dimensions of the load-bearing profiles are minimized. The low proportion of edge seal on the façade improves the Uw-value.

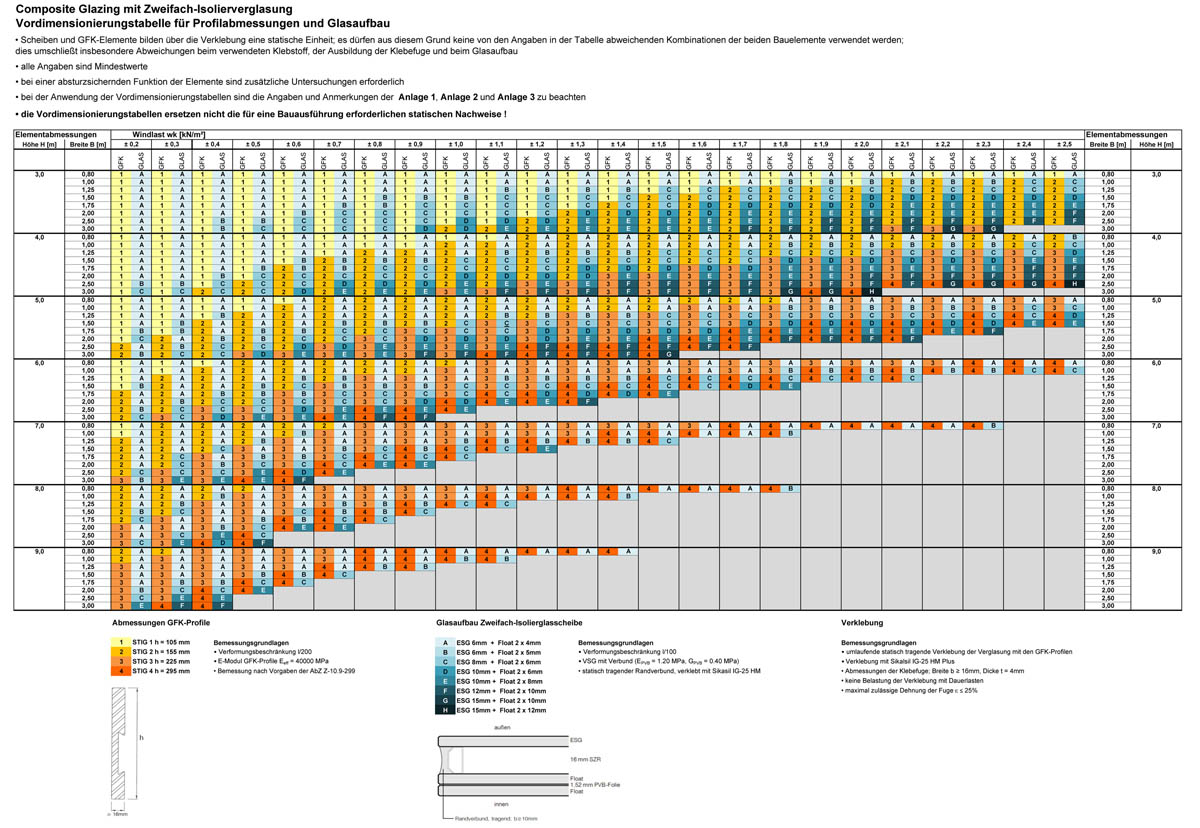

Within the scope of project development, ENGELSMANN PETERS carried out extensive calculations which are summarised in pre-dimensioning tables: depending on the parameters of element height, width and wind load, the glass structure and one of the 4 different GRP profile sizes can be selected. Pre-dimensioning tables have been prepared for double and triple insulating glazing.

Client

Fiberline Composite / Glass Trösch

Our service

Structural design LP 1-5

Product development

2007-2010

Photos workshop

Glass Trösch